24 June 2023

Following difficulty with the gearbox last year (it wouldn't select easily into forward, and then only turned slowly) a quick look in the box showed little oil and evidence of loose filings. Not good. My friend Spencer at the club offered to slip the gearbox out over winter while she was ashore and have a look. In order to do that, he had to get the engine out and into the cabin.

Spares for that gearbox are not available. A reconditioned replacement gearbox would be £600 + vat. The old Sea Panther engine, which has a history of being difficult to start, was already out. So after a bit of thought I decided not to put the old engine back in and instead to source a new engine + gearbox. Spencer has re-powered a few boats at the club and was kind enough to find time for this project.

Marine Enterprises are very helpful on the phone but items on their web site bear no relation to what they actually have available. So there was no Beta engine around. But there was a Perkins M30. Freshwater cooled, the same layout as the Sea Panther, 30hp (the old one was about 28hp). A 'used' engine - meaning, cleaned and serviced and bench-tested but not fully rebuilt. Apparently dating from the early 1990s so about twenty years younger than the old one. Described as an 'engine package' meaning engine, gearbox and loom. Brief research showed other Centaurs with that engine and no bad rumours. So a deal was done.

Spencer managed to get the old engine out and down to the ground in mid March using chains and the boom while Bay Leaf was ashore, and it was crated up ready to go in part exchange.

After a few weeks delay, and unfortunately after the boat had been craned back into the water, the new one arrived in late April.

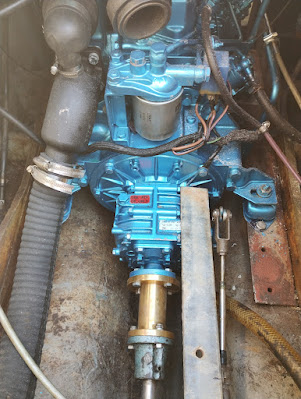

Somehow Spencer got this down to the boat and swung aboard using the boom, then he commenced the installation. This engine is 3 cylinder and physically shorter than the old 4 cylinder one so a coupling was fabricated from brass to allow the new gearbox to meet the old propshaft. A bit of steel was added to attach the gear selector cable. We also took the opportunity to fit a new exhaust hose and muffler box (which had been condemned in my 2019 survey report so needed doing anyway).

Time was spent on the engine mounts and alignment, some more new steel was fabricated, but by early June it was installed and running. The incoming sea water hose and outgoing exhaust pipes were all in the right place already, as this engine is the same way round as the old one. Spencer described it as 'half an engine' meaning that a lot of the hoses and connectors were not present and had to be purchased or fabricated. A lot of fiddling and fettling and man-hours.

Spencer spent a lot of time with feeler gauges to set these engine mounts such that the propshaft and the engine lined up properly. We used the Perkins control panel that had come with the engine, junking Bay Leaf's old instruments, but retaining the original separate gear and throttle levers.

I have been worrying the whole time that Bay Leaf's prop would be the wrong 'hand' for this engine but it turns out to be okay - when selected forward, she drives forward. Test-running in the berth showed a water drip from the impeller housing which had to be stripped and reassembled. Tickover had to be backed off as it was high which meant she drove quite hard even at the lowest possible position of the lever. But she starts right away on the key with no need to pump the fuel or squirt the Easy Start like the old one needed.

(rev counter not yet connected)

Good output on the exhaust

On 27 June Spencer took us for a short test drive in the Arun. At low revs there is very little prop kick, she went forward and back with no problem. With a few more revs she easily leapt to about 6kts through the water. Any more revs gave a trembling, buzzing feeling like the prop was cavitating so we may need a bigger prop - job for the winter perhaps. Meanwhile she's fast and smooth at low revs, much quieter than the Sea Panther, feels great.

I will now discard all my old engine spares (and the Easy Start) and get some new Perkins spares such as belt, impeller, filters. But this engine is freshly serviced so I don't expect to do anything to it till 2024.

Project cost, noting that Spencer was generous with his time and spent at least 50 hours on this project as well as driving around sourcing components:

- Used Perkins M30 £2195 +vat +delivery - £200 trade-in on the Sea Panther

- Various parts including exhaust hose, fabricated metal bits, stop cable, etc. £640

- Labour £1000

- Total cost of re-powering Bay Leaf £4136

Which is a lot to spend on a Centaur that I only paid £5k for, but, I now have a boat with a solid hull, sound keels, strong engine, high reliability, more than enough power to push me along the River Arun, and a lot more confidence in her ability to get me to places!

UPDATE - Spencer has made his own video diary of this job which can be viewed

here.

Comments

Post a Comment